THE FUTURE OF MANUFACTURING IS LOCAL HYPER/LOCAL.

Offshore manufacturing halfway around the world isn't as compelling as it once was. Parts shouldn’t have to be produced and shipped 10,000 miles from an overseas factory.

SWITCH FROM OVERSEAS TO LOCAL MANUFACTURING.

Antonym helps manufacturers move their manufacturing to the cloud and closer to home. Harnessing the power of cloud-based digital supply chain, Industrial Metal Additive Manufacturing & Robotics, we give you everything needed to start producing locally.

It's coming home

〰️

It's coming home 〰️

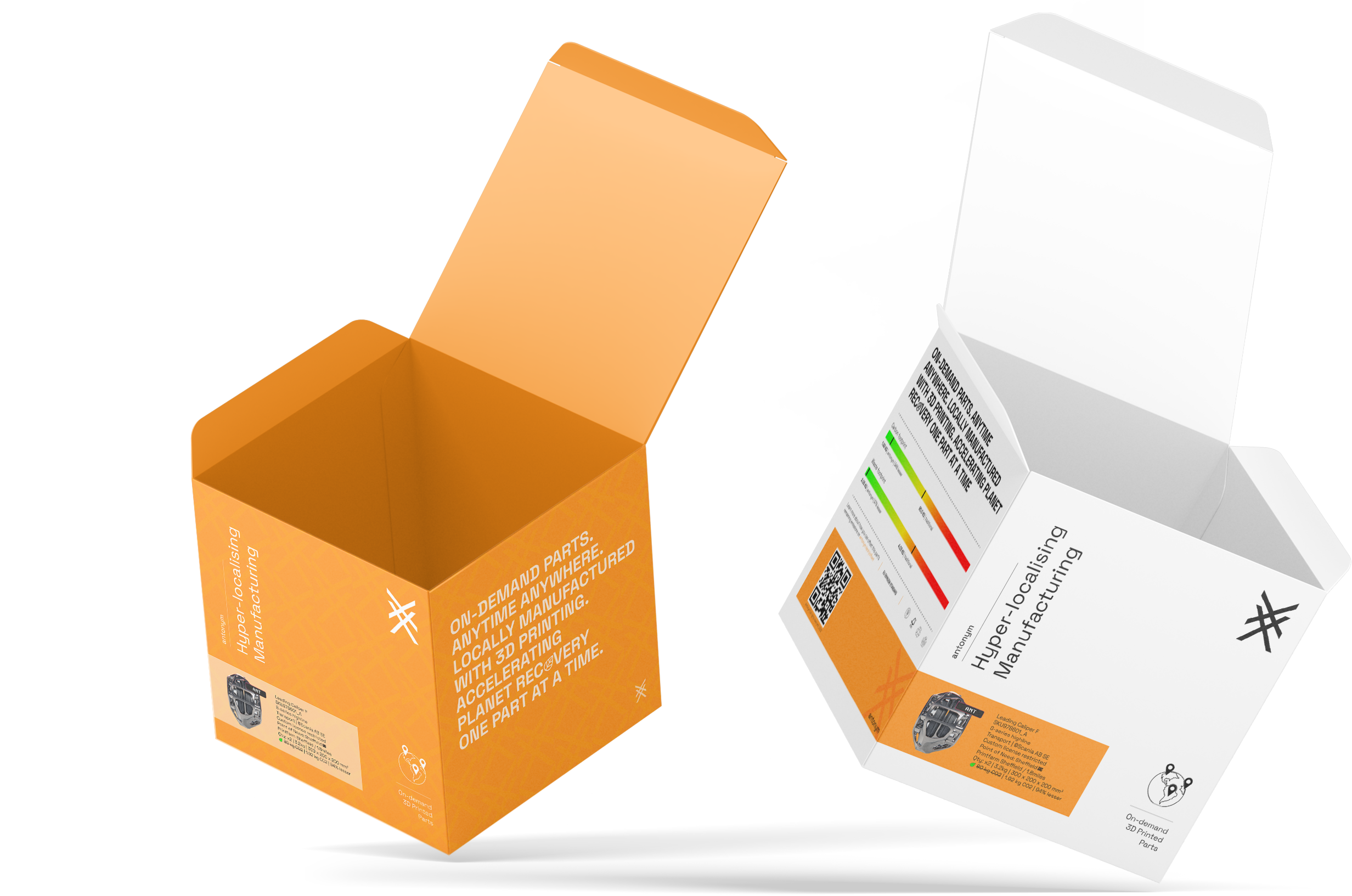

Antonym Distributed Additive Manufacturing (ADAM®) is a turnkey solution for local manufacturing. ADAM® enables industries to digitise their supply chains on the cloud and locally manufacture precision metal parts on-demand with Metal 3D Printing. Antonym’s full-stack solution combines micro-factories & software to help industries re-shore their manufacturing and produce precision parts and components faster, cheaper, & greener.

INTRODUCING ADAM

-

Digitise & store parts in virtual warehouses on the cloud as a "ready-to-print" library of parts. Digital parts can be virtually accessed for on-demand. 3D Printing anytime, anywhere.

-

Sell digital part licences instead of physical parts. Create new licences or choose from pre-sets, set restrictions, limit the quantity & sell parts on e-commerce marketplace.

-

Digitally ship designs instead of physically shipping parts. Our software streams design & manufacturing instructions over the internet to microfactories for one-click remote 3D Printing.

WE SELL FACTORIES AND THE SOFTWARE TO RUN THEM.

Our modular autonomous micro-factories and powerful, cloud-based digital supply chain software platform enables you to start producing closer to your customers without the CAPEX, lead times, and infrastructure risks of large centralised factories.

Trusted by industry leaders

-

"Antonym's digital supply chain has been pivotal in our decision-making process. Reshoring critical machine parts for our pressing machines has reduced lead times dramatically, from 2.5 weeks to just 6 hours. In an industry where lead times equals dictates, Antonym has made it possible for us to get our parts quicker, without compromising on the cost or quality compliance."

Operations Engineer, FTSE100 manufacturing enterprise

-

"Local manufacturing has always been a buzzword in our world of spare parts, but the cost of nearshoring or reshoring was just too high to justify without passing the costs down to our customers. With Antonym, we produced propulsion spare parts near our end use far cheaper than our current supplier in East Asia."

Factory floor manager, Aviation OEM

-

"The catch 22 of bulk volume anticipatory manufacturing always leads us to account for inventory wastes. In the past, more than 20% of our working capital was tied up to stock, and with Antonym's on-demand microfactory manufacturing, we now produce low volume high value parts as and when we need them."

Inventory comptroller, Heavy transport

Better for the business, the customer, and the planet.

Metal parts produced autonomously and hyper-locally using Antonym’s distributed network of microfactories. Antonym’s local production system is an orchestrated symphony of softwares, machines, and robots in one containerised production system to produce parts at the same speed and scale of softwares.

4x faster

30% cheaper

80% greener

-

Parts locally 3D Printed in 24-48 hrs. Shorten supply chains, slash lead times and avoid downtime losses.

-

Radically reduce inventory & shipping costs, import/export tariffs, carbon penalties & achieve lower TCO/part.

-

Reduce off-shore dependence, avoid supply chain breakdowns with locally 3D printed parts.

-

Parts produced at the very point of consumption, eliminating 82% of all shipping miles and CO2 & GHG emissions.

-

Proprietary tech ensures parts are of same quality & consistency in all globally distributed print locations.

-

Parts made to order, significantly reducing inventory costs. 64% of all excess stock & obsolescence wastes reduced using on-demand just-in-time manufacturing

-

Containerised manufacturing means a low-cost, modular, easily deployable and highly scalable solution.

We help high-value critical & frontier industries with their immediate parts needs.

Aviation

Space

Defence

Transport

Energy

Healthcare

6 tonnes

Six metric tonnes of precision metal parts (Titanium, Aluminium, Nickel, & Inconel) printed and delivered to customers in aerospace, energy, and transport applications.

3 ships

Three cargo ships equivalent GHG & CO2 emissions removed with local production closer to the point of need. ~26,000 nautical miles eliminated from supply chain.

3.8 tonnes

equivalent weight of inventory wastes and part scraps eliminated with on-demand Just-in-Time (JIT) manufacturing. No more excess stocking or obsolescence.

£30k

Annual carbon penalty savings achieved by customers per year with reduced scope 3 emissions. Triple bottom line approach to accelerating planet recovery.

FACTORY AS A SERVICE. ANTONYM TURNS YOUR CAPEX INTO OPEX.

We are all about helping you combat the inertia of change. We own and operate all our microfactories, and you own a part of the production capacity. Antonym’s Factory-as-a-Service (FaaS) solution allows industries to produce parts locally closer to demand without the high CAPEX, risks, & lead times of building new factories in new locations or meet new needs.

34% less CAPEX

The tailwinds are in favour of local manufacturing

61%

Supply chain leaders anticipate decline in offshore production in the next 5 years

64%

Manufacturers are embracing Just in Time on-demand manufacturing

85%

Manufacturers assert that 3D Printing will play a dominant role in their business

84%

Supply chain leaders are prioritising investments in supply chain resilience

*2022 State of Manufacturing Report (Fictiv)

GO LOCAL WITH US.

Book a free 30-minute call to help us help you decide if local manufacturing is right for you. You’ll have the opportunity to try out our FactoryOS digital supply chain software, generate and download ROI/PSF reports.

IN A GOLD RUSH TO RESHORE MANUFACTURING, ANTONYM IS SELLING SHOVELS. WE PROVIDE A LOCAL ALTERNATIVE TO OFFSHORE FACTORIES.

INVESTORS

Access our investor data room

FROM BRITAIN TO THE WORLD

Hours

Monday–Friday

9am–6pm

Phone

(+44) 0 7432 829 180

Address

32 Park cross street

Leeds, LS1 2QH, United Kingdom

Email

rev@antonym.tech